The demand for water glasses in Pakistan is consistent throughout the year, as households, hotels, restaurants, and catering businesses rely heavily on glassware. Starting a Water Glass Making Business can be a profitable small-to-medium scale manufacturing idea with great potential for growth.

This business involves producing high-quality drinking glasses made from glass material through processes like molding, cutting, polishing, and packaging. With proper machinery and skilled labor, you can start production locally and supply to wholesale markets, retailers, and even export internationally.

Why Start a Water Glass Manufacturing Business?

- High Demand: Every home, hotel, and office needs water glasses.

- Profit Margins: Glass products have reasonable margins due to low raw material costs.

- Scalability: Start small and gradually expand into producing glass sets, jugs, and decorative glassware.

- Export Potential: Pakistan-made glassware has demand in the Middle East, Africa, and South Asia.

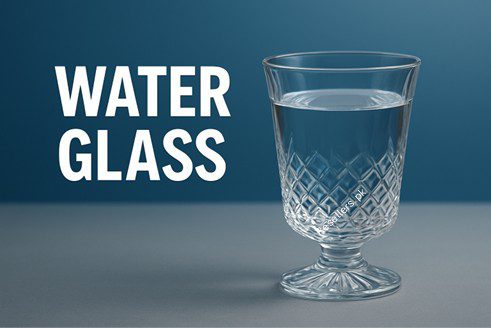

Investment & Requirements:

- Small Scale Investment: PKR 15 – 20 lakh (for basic setup with semi-automatic machines).

- Medium Scale Investment: PKR 50 lakh+ (with advanced machinery for bulk production).

- Raw Materials: Silica sand, soda ash, limestone, cullet (recycled glass).

- Machinery: Glass furnace, molding machine, annealing kiln, polishing machine, packaging unit.

Profitability:

Profit margins in the water glass making business can range from 20% to 40%, depending on production capacity, design, and market reach. With bulk production and strong distribution channels, the business can scale into a successful manufacturing unit.

Conclusion:

Starting a Water Glass Making Business in Pakistan is a practical and profitable manufacturing idea. With growing demand in households and commercial sectors, entrepreneurs can earn stable income and expand into domestic and export markets.